Dolphin

Professional to provide

non-teaching independent decision-making welding system”

Dream,continues,toward the front, i strive to run

Company concept

Customer-oriented, centered on customer value.

Company mission

Leading the intelligent welding revolution with innovation.

Video introduction

Visual recognition & no programming

Leading the intelligent welding revolution with innovation

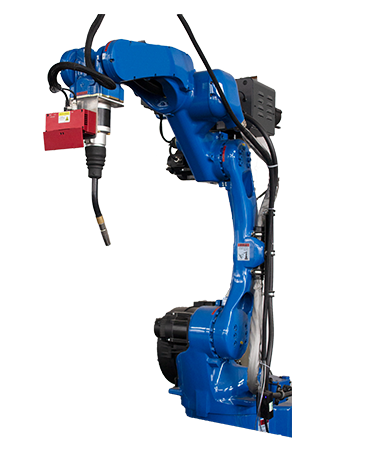

Support the robot ecology

It has a standardized universal open interface to support a variety of robot and welding equipment brands on the market

Support welding needs

With a variety of sensors, suitable for different forms of carbon steel structure welding, flexible manufacturing is the only choice.

About Us

About Company

Our company has 3 factories both overseas and domestic

In China Pakistan Algeria

Dolphin Smarts is a focus on the research and development of non-standard metal industry for teaching independent decision-making welding system technology enterprises. The company independently developed the non-programming teaching and autonomous decision-making welding system, using view processing, motion planning obstacle avoidance, environmental perception and behavioral decision-making technology, improve the intelligence of the robot, and strive to achieve automatic welding of the whole process.

- Dolphin Smarts

- SunTang Technology

- Sarl-UCMAC

DOLPHIN

Core highlight

_____

In order to respond to the call of the state and promote the application of welding robots in steel structure engineering, chemical equipment manufacturing and other industries, the company has independently developed a self-decision-making welding system without teaching. The system can be matched with various types of mainstream robots and welding machines, and can realize automatic welding without programming. Dolfin intelligent manufacturing strives to reach a new high in the field of welding, breaking the cumbersome operation process of traditional robots, and creating a new intelligent welding system without teaching and autonomous decision-making.

Real-time 3D animation

Through real-time 3D animation combined with embedded motion planning simulation model, pre-demonstration of welding trajectory and real-time display of welding status can be achieved.

Automatic welding process

Automate the welding process by clicking a button on the software interface

High degree of freedom adaptation

Open interface design, and can be quickly adapted to the external axes carried by the robot, including but not limited to the ground rail, gantry, positioner, etc

High adaptability to environment

Suitable for a variety of welding scenarios, including but not limited to non-standard steel structures, non-standard metal workpieces, etc

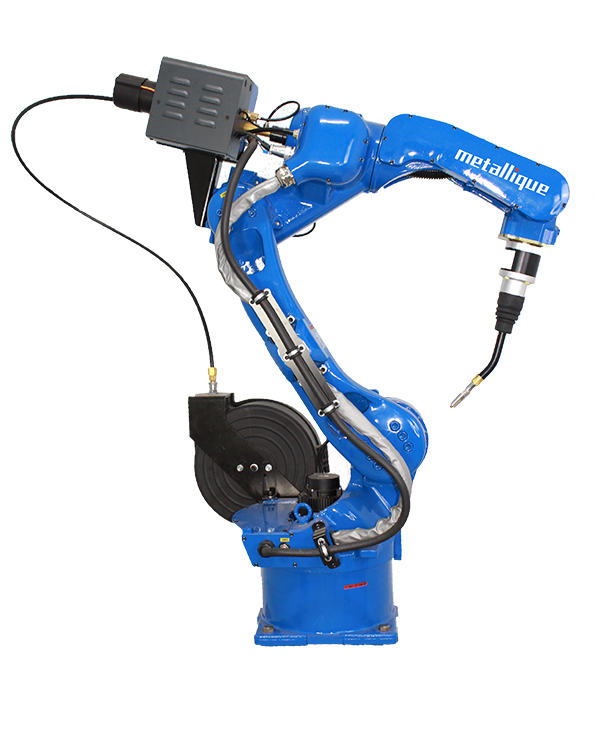

Product introduction

Phase one

Self-decision-making welding system without instruction

The system integrates motion control algorithm, machine vision, autonomous obstacle avoidance algorithm and welding process design. The system provides independent planning function based on image recognition and feature analysis, and provides data support and core obstacle avoidance planning for automatic welding process.

Dolphin Smarts

Teaching device (intelligent remote control handle)

The use of gamepad-like controller and operation mode eliminates complex programming and reduces operator technical requirements.

Dolphin Smarts

Smart teaching pen

Using digital tracking technology and wireless positioning technology, the intelligent teaching pen is developed.

Just wave the simulated path, you can complete the teaching.

Dolphin Smarts

Advantage

Our advantage

Independent R&D, independent design

Independently developed, designed and produced intelligent peripherals; Independent development of a new visual, whole-process automatic welding welding intelligent manufacturing equipment, no programming.

Overseas factories, strong capital

The overseas department of the company is mainly engaged in steel structure engineering and chemical equipment manufacturing, and has a strong financial background to support technology development. It is a common enterprise in manufacturing practice and scientific and technological research and development.。

Professional, experienced

The company's core R & D team, familiar with industry dynamics, strong technical strength. A clear understanding of the future situation of intelligent welding robots.

Step into autonomous decision-making welding?

Dolphin Open platform

Open research platform in welding robot field

In order to promote the intelligent reform of welding robots, Dolfin Intelligence built the Dolphin software system based on the self-developed open system architecture, which can provide a stable, reliable and featurely-rich secondary development interface.