Dolphin intelligent non-teaching welding system open for sharing!

The Dolphin Intelligent Teachable Welding system will be available for sharing from January 1, 2024! Win-win cooperation to build the future ecology, open and share to promote industry change!

Dear users, thank you for your attention and support to Dolphin Intelligence all the time. In order to give back to the vast number of robot integrators and robot ontology customers, and to promote the development of the welding industry and stimulate the development potential of the industry, we are very pleased to announce that the Dolphin Intelligent non-teaching welding system will be open to share from January 1, 2024!

the background and significance of open sharing

With the rapid advancement of industry 4.0 and intelligent manufacturing, automatic welding has become the development trend of the industry, and robot teaching has gradually become an important technical means in the field of industrial welding. However, the teaching process of traditional welding systems is cumbersome, time-consuming, and requires high skills of operators. In order to solve this problem, Dolphin has successfully developed a non-teaching welding system with its deep accumulation in robotics and artificial intelligence. The system can greatly improve the efficiency and quality of welding, reduce the difficulty of operation, so that more users can easily apply robot technology, and help more enterprises to realize welding automation.

The open sharing of Dolphin's intelligent non-teaching welding system is an important step for us to advance the robot welding industry. We hope that through this initiative, we can help more enterprises realize welding automation and improve production efficiency and quality. At the same time, we also look forward to working with the majority of users to explore and promote the innovation and development of welding technology. Break through the boundaries to stimulate the vitality of innovation, embrace change and promote the development of the industry.

The content and advantages of open sharing

1. Content: Dolphin intelligent non-teaching welding system and system secondary development and application will be free and open to share. Users can obtain and use the system through application to fully meet the needs of steel structure welding.

2. Schedule: It is planned to be officially opened and shared on January 1, 2024.

3. The plan is to open 30 partners, each partner can be authorized without limit, first come, first served.

4. Advantages:

a) Cost saving: Free and permanent use of domestic technology leading Dolfin intelligent non-teaching welding system to achieve efficient welding of steel structure components.

b) Improve efficiency: non-teaching welding system is an automatic welding system based on machine vision and artificial intelligence technology, visual identification without programming, can automatically identify and plan the welding path, robust autonomous obstacle avoidance function also greatly improve welding efficiency.

c) Reduce skill requirements: no professional welding engineer is required, ordinary workers can operate after simple training.

d) Flexible customization: Users can freely modify and expand system functions according to their own needs, and easily cope with complex welding tasks of steel structure workpieces.

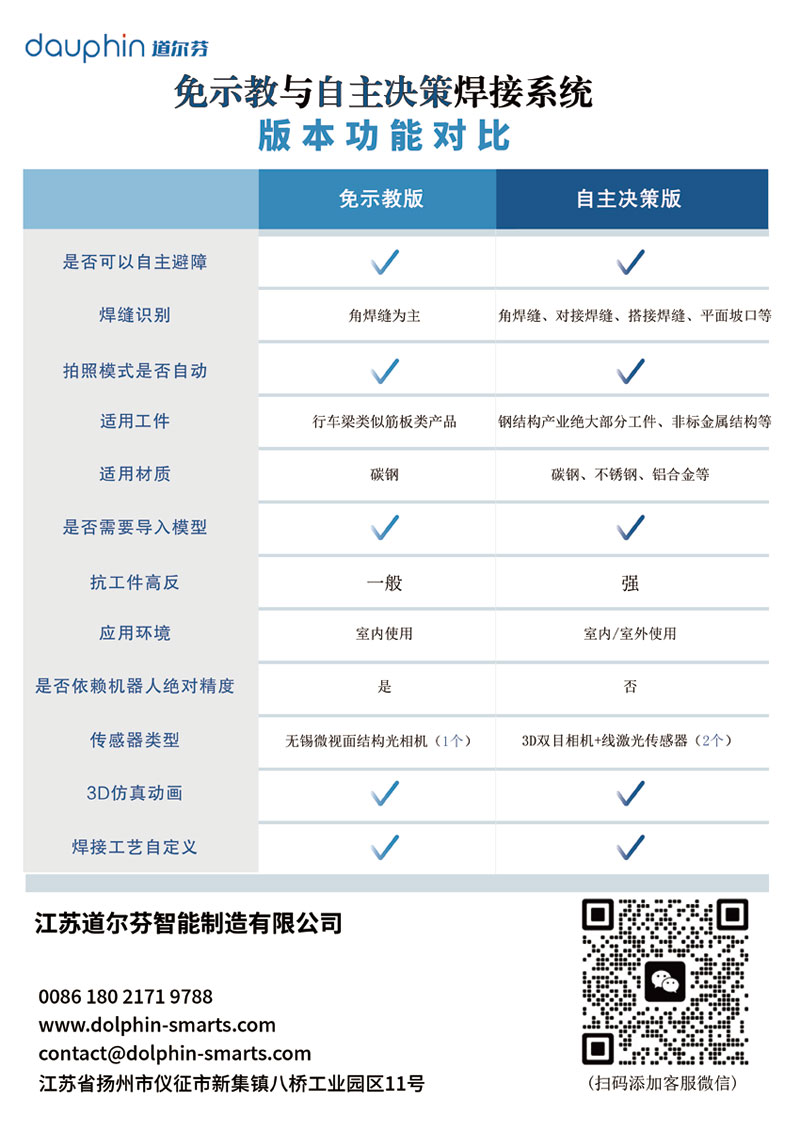

no teaching and autonomous decision-making welding system version function comparison

Extension: Advantages of autonomous decision-making welding system

a) The first "vision + line laser" perception mode: the "vision + line laser" perception mode of DLP 3D structured light camera + binocular line laser camera is used to optimize the welding scene of metal components, solve the problem of the impact of high workpiece reflection and ambient light on the image quality of the sensor, and achieve sub-millimeter weld identification accuracy.

b) Automatic obstacle avoidance welding: The system independently plans the welding trajectory according to the workpiece model, and realizes the robot autonomous obstacle avoidance function for complex workpiece, in order to avoid various problems caused by collisions in the welding process.

c) Welding trajectory accuracy within 1mm: Combined with the 3D model analysis module of Dolphin's autonomous decision-making welding system, the six-axis robot is driven to achieve welding trajectory accuracy within 1mm in non-standard welding scenarios by robot motion control algorithm and dynamic simulation correctness check calculation, so as to get rid of the system's dependence on the accuracy of the robot body.

d) Wide range of applications: the system can be used for multi-variety, multi-size component welding, in steel structure engineering, engineering machinery, grain machinery, aerospace and military, Marine engineering, mining machinery, petrochemical industry, building formwork, metallurgical equipment, lifting machinery and other industries can be applied.

Application and use of open sharing

1. Users can apply: robot system integrator, robot ontology company.

2. How to apply: Users can submit the application through the official website of Dolfin by phone, private wechat or wechat public account, we will review and reply as soon as possible.

3. Audit criteria: The company has a large scale, a certain project ability and experience, and customers with project after-sales ability are preferred.

4. Use process: After passing the audit, the user will get the encrypted U disk of the system, and provide the use of the tutorial and operation manual. Install and configure the hardware according to the guide.

5. Configure hardware. For details, see the operation manual.

6. Open validity period: For the companies that have reached cooperation, the free teaching version is granted permanent open permission

Technical support

1. Technical support: Dolphin provides comprehensive technical support, including online consultation and offline training, to ensure that the problems encountered by customers in the process of use are solved in time. 2. Service guarantee: We provide system version upgrade, maintenance and personalized solution customization and other service guarantees to ensure that users can stably and efficiently use Dolfin intelligent non-teaching welding system.

Conclusion and prospect

In the future, we will continue to invest more research and development strength and resources, and constantly optimize and improve Dolfin intelligent non-teaching welding system, to provide users with more efficient and intelligent solutions. Lead the welding revolution with innovation, and help the development of robot non-teaching welding industry.

Let us work together to create a new chapter of automatic welding!

(The final interpretation of this activity belongs to Jiangsu Dolfen Intelligent Manufacturing Co., LTD.)